NEES News

UMD Researchers Create New Architecture for Solid-State Li-ion Batteries

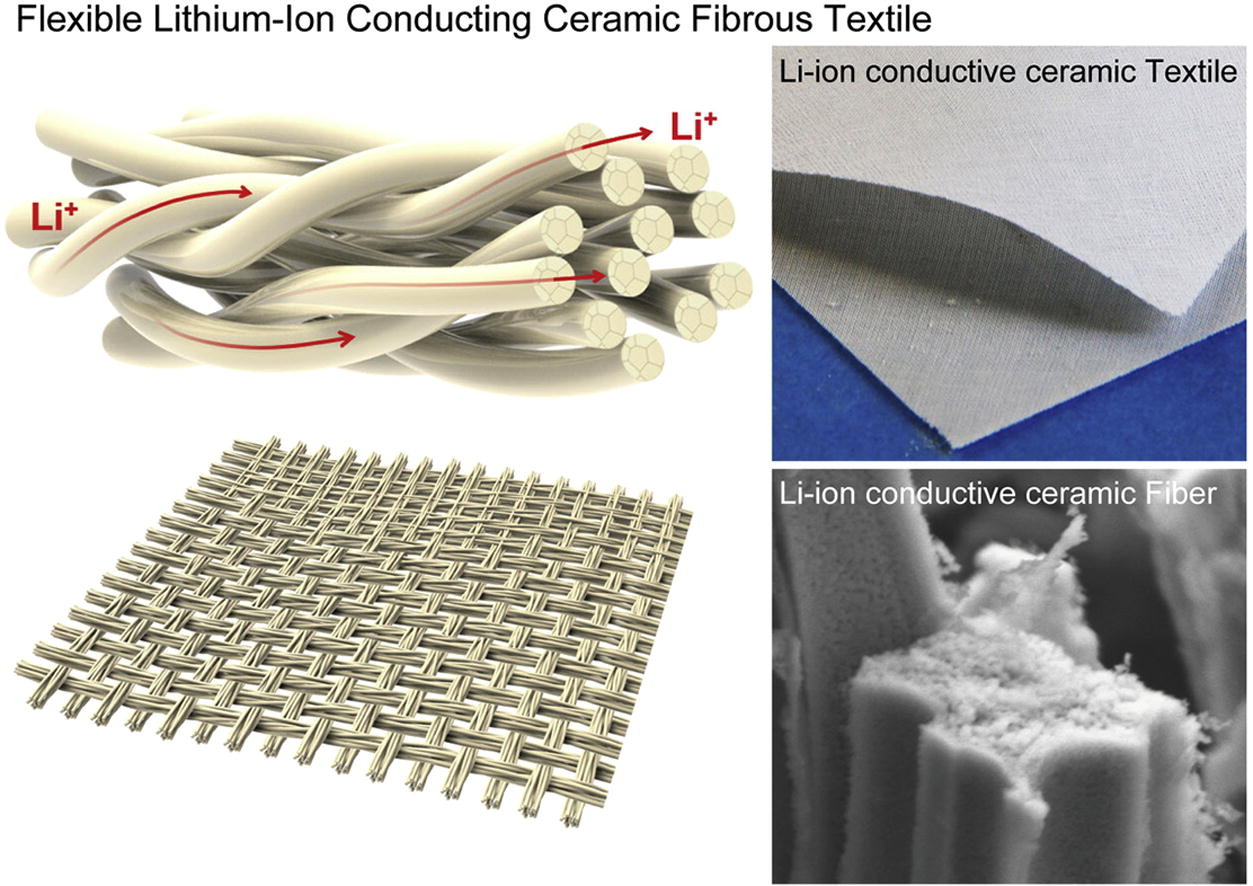

In the last few years, much time, effort and resources have been put into the development of battery technology that is safe, efficient, cheap to produce, and eco-friendly. Conventional Lithium-ion (L-ion) batteries typically use liquid electrolytes due to their very high ionic conductivities; however, these liquid electrolytes have numerous drawbacks including flammability, leakage and the formation of dendrites in the electrodes. In an effort to avoid these issues, researchers at the University of Maryland Clark School of Engineering – led by Eric Wachsman (Professor with appointments in both MSE and ChBE and Director of the MD Energy Innovation Institute) and Liangbing Hu (MSE Professor) – have focused their efforts on the development of solid-state-batteries, in this case, utilizing a solid non-flammable ceramic electrolyte known as garnet. The study, entitled, “Lithium-ion conductive ceramic textile: A new architecture for flexible solid-state lithium metal batteries,” was published online February 2 in Materials Today. Yunhui Gong, a postdoctoral fellow in Materials Science and Engineering, served as the paper’s first author. “The goal of this research is to develop safe solid-state components for use in lithium-metal batteries,” said Dr. Gong. “Such components should have good ionic conductivity, abundant surface area and scalable production potential. We have successfully developed a garnet-fiber textile to meet these key requirements.” In their research, the team used commercially available fabrics as a template for creating Li-conducting garnet fiber mat textiles, and then filled in the pore space between the fibers with a solid polymer electrolyte. The result is a highly scalable process to make hybrid ceramic/polymer Li-electrolytes with the enhanced properties of higher conductivity and strength of the garnet ceramic electrolyte. Moreover, the ceramic textile is flexible and cut-table. “Nothing like this has ever been done before,” Dr. Wachsman stated. “The resulting hybrid structure is capable of fast-ion conduction through the continuous ceramic fibers, but with the flexibility of more traditional polymer electrolytes. What’s more, the garnet fibers will help block the formation of Li-dendrites, thus enabling higher capacity Li-metal anodes.” The group intends to continue their research with this technology, planning to make the textile even thinner to reduce resistance to ionic transport between electrodes. The technology will have a wide-range of applications in commercial electronics. For additional information: Gong,Y. et al., Hu, L. Wachsman, E. “Lithium-ion conductive ceramic textile: A new architecture for flexible solid-state lithium metal batteries.” Materials Today, published online 2 February 2018. DOI: 10.1016/j.mattod.2018.01.001 Related media: UMD Researchers Find Ultra-thin Solution to Primary Obstacle in Solid-State Battery Development - UMD, 12/2016

February 22, 2018 Prev Next |