NEES News

Atomic Layer Depostion and Graphene Inspire Creative Catalyst Design

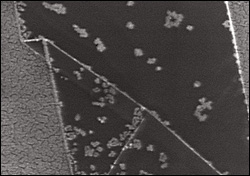

Department of Materials Science and Engineering (MSE) graduate student Alex Pearse, advised by MSE professor and Maryland NanoCenter director Gary Rubloff, received a 2014 Hulka Energy Research Fellowship from the University of Maryland Energy Research Center (UMERC) for his proposal to create new high-performance, transparent, conducting thin films and other novel photoelectrochemical catalysts. Pearse will use atomic layer deposition (ALD) and other purpose-designed assembly methods to exploit the unique properties of graphene, which will serve as the foundation of these new materials. The best photoelectrochemical catalysts, Pearse says, are those with highly reactive surfaces, high transparency to reduce light scattering, strong coupling to their electrodes, high surface activity, and the ability to manage intermediate reactions. Few if any catalysts, however, possess all of these qualities. Photoelectrochemical cells, which convert sunlight into chemical energy, contain a catalyst that consists of a support layer of a material that absorbs light and generates electrons, covered by a thinner layer of catalyst particles. The electrons travel into the catalyst particles, where they can participate in electrochemical reactions with nearby reactants. “Graphene is an ideal support for catalyst particles on because it’s highly conductive, and when it’s only a few sheets thick, it’s also transparent,” Pearse explains. “The best catalyst is a thin film of a noble metal like platinum. The problem is that metals are not transparent. The more metal you put down, the more light you block from entering your electrode. The efficiency of the system decreases despite the combination of two very good materials.” But if you could control the placement of the catalyst particles at the atomic level, he theorizes, you could design a photoelectrochemical catalyst with the best balance of reaction sites and transparency, one atom at a time. That’s where ALD comes into play. ALD is a procedure used to create atoms-thick films for a variety of applications, often in the semiconductor and electronics industries. Material is deposited on a supporting surface called a substrate at the atomic scale and in specific locations or patterns. ALD makes it possible to manufacture devices and apply coatings with nanoscale precision. Combining ALD and graphene, Pearse says, is a little unusual because the flat plane of a sheet of graphene is usually unreactive. Because of this the ALD process can’t bind the catalyst particles to the plane, making it an unsuitable substrate. But the edges of the sheet are highly reactive, and this allows him to get creative. “You could make a film of graphene flakes on a substrate, giving you a high density of exposed edges,” he says. “The ultimate example of high surface area is if you have isolated catalyst atoms on these edges, because every side of every atom is available for reaction. Since ALD lets you precisely control how much you put down and where, you can also control the density of your catalyst, which affects what kind of catalytic activity occurs.” Among other applications, these graphene catalyst composites could be used in lithium-air batteries or for photoelectrochemical water splitting, the direct conversion of sunlight into chemical energy using solar cells. Pearse is excited about the prospect of working on something brand new, and says the Hulka Fellowship makes the still-speculative work possible. “When you combine ALD’s precision with graphene’s unique ability to allow deposition at some places but not others, it becomes possible to create a whole new class of composite materials,” he says. Hulka Energy Research Fellowships support graduate students engaged in selected fields of alternative energy research, including solar energy conversion, biofuels, wind energy, wave energy, and ocean thermal or geothermal energy. Hulka Energy Research Fellows receive up to $20,000 to complete a one-year personal project distinct from the research they perform for their advisors.

September 12, 2014 Prev Next |